Understanding the materials that build our world is crucial, especially in industries reliant on durability and performance. Modified asphalt, particularly polymer modified asphalt, represents a significant advancement over traditional materials. This article delves into the world of polymer modified asphalt binders, explaining what they are, the benefits of modified materials, the types of asphalt modifiers used, and why they are becoming essential for modern infrastructure projects like roads and roof applications. If you're involved in purchasing or specifying asphalts, especially for demanding applications, understanding asphalt modification is key to achieving longer service life and better value. This guide provides the insights you need, drawing from industry knowledge and practical experience.

What Exactly is Modified Asphalt and Why is it a Game-Changer?

At its core, modified asphalt is a type of asphalt binder whose properties have been enhanced by adding specific substances, known as modifiers. Think of standard asphalt as the base ingredient. While effective for many traditional uses, standard asphalts can sometimes fall short under severe conditions like heavy traffic load, extreme temperatures, or specific industrial requirements. This is where modification comes in. By incorporating additives, we can tailor the asphalt's characteristics to meet higher performance demands.

The concept isn't entirely new, but the sophistication of asphalt modifiers and the understanding of their interaction with the base asphalt have evolved significantly. The goal is typically to improve elasticity, strength, adhesion, resistance to deformation (like rut formation in roads), and durability against thermal cracking or fatigue. Essentially, modified asphalts are engineered materials designed to outperform conventional asphalt pavement or roofing asphalts, offering a longer lifespan and reduced maintenance over time.

For professionals like Mark Thompson, who procure materials for large-scale projects (aluminum smelters, steel mills, road construction), understanding the 'why' behind modified asphalt is crucial. It's not just about buying asphalt; it's about investing in a material engineered for superior performance. Using modified asphalt can lead to significant long-term savings, even if the initial cost is slightly higher, by extending the life of the pavement or structure and reducing the frequency of costly repairs or replacements. It’s a shift from a simple commodity purchase to a strategic material selection.

How Do Polymers Transform Standard Asphalt Binders?

The most common and effective way to create modified asphalt is through the addition of polymers. A polymer is a large molecule composed of repeating structural units. When incorporated into an asphalt binder, these polymer chains interact with the asphalt components, forming a network or matrix that fundamentally changes the binder's behavior. This process is known as polymer modification. The resulting material is often referred to as polymer modified asphalt (PMA) or polymer modified binders.

The transformation occurs at a microscopic level. The polymer doesn't just mix physically; it often creates a distinct phase within the asphalt binder, influencing its rheological properties (how it flows and deforms). Depending on the type and concentration of the polymer used, the modified asphalt can become more elastic (able to stretch and recover), tougher (resistant to fracture), and less susceptible to temperature changes. For instance, it might retain its stiffness better at high temperature to resist rutting, while remaining flexible enough at low temperature to prevent thermal cracking.

From our experience as a supplier (ZGFTY), producing a consistent and high-quality polymer modified asphalt requires careful control over the mixture process. Factors like the type of base asphalt, the specific polymer chosen, the mixing temperature, time, and shear energy applied are all critical. Achieving proper dispersion and stability of the polymer within the asphalt is key to unlocking the desired performance enhancements. An improperly mixed polymer modified asphalt might not deliver the expected benefits and could even perform worse than an unmodified binder. This meticulous production process is why partnering with an experienced manufacturer is vital.

What are the Key Benefits of Using Polymer Modified Asphalt (PMA)?

The widespread adoption of polymer modified asphalt stems from its tangible advantages over conventional asphalt binder. For procurement officers and company owners focused on both quality and long-term cost-effectiveness, these benefits of modified materials are compelling. The primary goal of using a modifier, especially a polymer, is to enhance specific performance characteristics of the pavement or roofing material.

Here are some key benefits:

- Improved Rut Resistance: PMA significantly enhances the asphalt mixture's ability to resist permanent deformation (rut) under heavy traffic loads, particularly in hot climates. The polymer network provides greater stiffness and elasticity at high temperatures.

- Enhanced Resistance to Fatigue Cracking: The increased elasticity allows the pavement to better withstand repeated loading cycles without developing fatigue cracks, extending its service life.

- Reduced Thermal Cracking: At low temperatures, polymer modified asphalt remains more flexible than conventional asphalt, reducing the likelihood of shrinkage cracks (thermal cracking) caused by cold weather cycles.

- Better Adhesion: Many polymer modifiers improve the adhesion between the asphalt binder and the aggregate particles in the mixture. This reduces the risk of moisture damage and "stripping," where the binder pulls away from the aggregate.

- Increased Durability and Lifespan: Combining these benefits leads to a more robust asphalt pavement or roofing shingle that lasts longer and requires less maintenance, lowering life cycle costs. Studies and field performance data often show roads made with PMA lasting significantly longer compared to conventional asphalt.

- Wider Temperature Operating Range: Modified asphalt generally performs well across a broader range of temperatures, making it suitable for diverse climates. Its susceptibility to temperature changes is reduced.

While the initial cost of PMA might be higher than standard asphalt, the improved performance and extended lifespan often result in lower overall costs when considering maintenance and rehabilitation frequency. This is a critical calculation for infrastructure projects with long-term budget considerations.

Exploring Different Types of Asphalt Modifiers: From SBS to Elvaloy™ Reactive Elastomeric Terpolymers

The world of asphalt modifiers is diverse, with various materials used to achieve specific performance enhancements in the asphalt binder. While polymers are the most common, other additives exist. However, focusing on polymer modifiers, two main categories dominate the market: plastomers and elastomers.

- Elastomers: These polymers impart rubber-like elasticity to the asphalt. The most widely used elastomer is styrene-butadiene-styrene (SBS), a block copolymer. SBS forms a continuous polymer network within the asphalt at sufficient concentrations, dramatically improving elasticity, flexibility at low temperature, and resistance to fatigue and rut formation. It's a workhorse modifier for high-performance asphalt paving applications.

- Plastomers: These polymers tend to increase the stiffness and viscosity of the asphalt binder, primarily improving high-temperature performance and rut resistance. Common examples include ethylene-vinyl-acetate (EVA) and polyethylene. While effective at boosting stiffness, they may not provide the same level of low-temperature flexibility as elastomers like SBS.

Beyond these, other notable polymer types exist:

- Reactive Polymers: A key example is Elvaloy™ Reactive Elastomeric Terpolymer (RET) from Dow Inc. These are reactive polymers, meaning they chemically bond with the asphalt components, forming a permanent, stable network. Elvaloy™ reactive elastomeric terpolymers, often simply called Elvaloy, offer excellent elasticity, toughness, and improved compatibility and storage stability compared to some non-reactive systems. This type of modification provides robust performance across a wide temperature range.

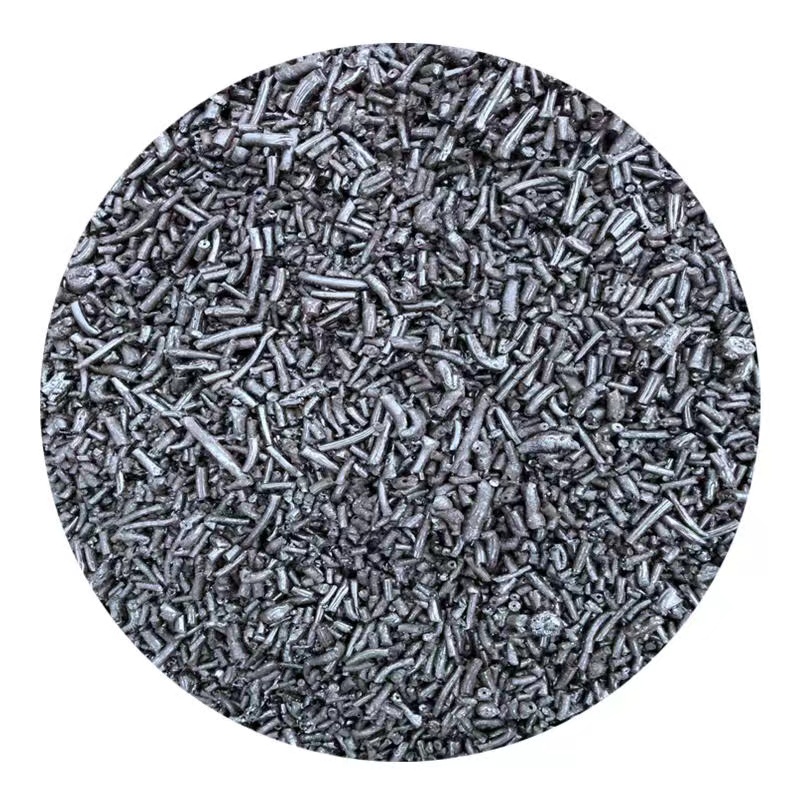

- Crumb Rubber: Derived from recycled tires, crumb rubber is another significant modifier. It improves elasticity and rut resistance but can sometimes present challenges in mixing and storage stability. Its use aligns with sustainability goals.

- Other Additives: Sometimes, non-polymer additives like acids (e.g., polyphosphoric acid - PPA) or anti-stripping agents are used, occasionally in conjunction with polymers, to further enhance specific properties like high-temperature stiffness or moisture resistance.

Choosing the right modifier depends heavily on the intended application, the climate, the traffic volume, the properties of the base asphalt, and the desired performance characteristics specified by frameworks like Superpave. As a supplier, we work with customers to select the optimal modified asphalt formulation, whether it's a standard grade or a custom blend incorporating specific polymer types like SBS or EVA. For demanding applications requiring robust performance, exploring options like our High temperature asphalt might be beneficial.

Can Modified Asphalts Handle Extreme Temperatures Better?

Absolutely. One of the primary drivers for developing and using modified asphalt, particularly polymer modified asphalt, is its enhanced ability to perform under extreme temperature conditions – both high and low. Conventional asphalt binders have a relatively narrow optimal temperature range. They soften significantly in heat, leading to rutting and shoving, and become brittle in the cold, leading to thermal cracking. Polymer modification directly addresses this susceptibility.

At high temperatures, the polymer network within the asphalt binder (especially with elastomers like SBS or certain plastomers) increases the stiffness and elastic recovery. This means the pavement resists deformation under heavy loads even when the sun is beating down. Imagine a heavily trafficked intersection on a hot summer day – PMA helps prevent those characteristic ruts from forming, maintaining a smoother and safer surface. Our Modified asphalt products are specifically engineered to offer this enhanced high-temperature stability.

Conversely, at low temperatures or during cold-temperature cycles, the polymer (especially elastomers) imparts greater flexibility to the asphalt binder. Standard asphalt contracts and becomes brittle as it cools, leading to stress buildup and eventual cracking (thermal cracking). Polymer modified asphalt can withstand greater strain before fracturing, significantly reducing the risk of these low-temperature cracks. This is crucial in regions experiencing harsh winters. The ability of modified asphalts to maintain integrity across a wider thermal range translates directly to longer pavement performance and reduced maintenance needs.

How is the Performance of Modified Asphalts Evaluated?

Ensuring that modified asphalt meets the desired performance characteristics requires rigorous testing and evaluation. The Superpave (Superior Performing Asphalt Pavements) system, developed under the U.S. Strategic Highway Research Program (SHRP), provides a comprehensive framework for characterizing asphalt binders based on their performance in relation to climate and traffic conditions. Polymer modified asphalt binders are commonly graded using the Superpave performance grading (PG) system.

Key tests used to determine the effect of modification and evaluate performance include:

- Dynamic Shear Rheometer (DSR): This instrument measures the rheological properties (viscoelastic behavior) of the asphalt binder at intermediate and high temperatures. It helps predict resistance to rutting and fatigue cracking by measuring complex shear modulus (G) and phase angle (δ). Higher stiffness (G) and elasticity (lower δ) are generally desirable at high temperatures. The DSR is crucial for Superpave grading.

- Bending Beam Rheometer (BBR): This test evaluates the low-temperature stiffness and relaxation properties of the asphalt binder. It measures how much the binder creeps (deforms) under a constant load at cold temperatures, predicting its susceptibility to thermal cracking. Lower stiffness and faster relaxation are preferred for better cold-temperature performance.

- Direct Tension Tester (DTT): Used to measure the failure strain of the asphalt binder at low temperatures, providing another indicator of thermal cracking resistance.

- Elastic Recovery: Tests measure the ability of the modified binder to recover its original shape after being stretched, indicating the effectiveness of the polymer network.

- Separation Test (Storage Stability): Since polymers and asphalt have different densities, tests are run to ensure the polymer remains evenly dispersed within the asphalt during hot storage, assessing the stability of polymer modified binders. Reactive polymers like Elvaloy often excel here.

- Microscopy: Techniques like fluorescence microscopy can be used to visually assess the polymer dispersion and network structure within the asphalt binder.

Beyond binder testing, performance is also evaluated using asphalt mixtures containing the modified binder. Tests on the complete mixture, like wheel tracking tests (for rutting), beam fatigue tests, and thermal stress restrained specimen tests (TSRST), provide further insights into how the modified asphalt will perform in the actual pavement. These comprehensive evaluations ensure that the performance of modified asphalt meets project specifications and delivers the expected benefits compared to conventional materials.

Are There Sustainable Options? Exploring Recycle and Plastic in Asphalt Modification

Sustainability is an increasingly important consideration in all industries, including asphalt paving and roofing. The asphalt industry has made significant strides in incorporating recycled materials and exploring more environmentally friendly modification techniques. Modified asphalt technology plays a role in these efforts.

One major area is the use of recycled asphalt pavement (RAP) and recycled asphalt shingles (RAS). These materials contain aged asphalt binder and valuable aggregate. Polymer modified asphalt can sometimes facilitate the use of higher percentages of RAP/RAS in new asphalt mixtures. The robust properties of the polymer modified binder can help compensate for the stiffer, aged binder present in the recycled materials, allowing for the creation of durable pavements while conserving virgin resources.

Another growing area is the use of recycled plastics as asphalt modifiers. Various types of waste plastic, such as polyethylene (from bottles and films) and polypropylene, are being investigated and, in some cases, implemented as partial replacements for or additions to conventional polymer modifiers. This approach offers a potential avenue for diverting plastic waste from landfills while potentially enhancing pavement properties. However, challenges remain regarding long-term performance, consistent processing, and potential environmental impacts (e.g., microplastic release), requiring ongoing research and careful implementation. Dow Inc. and other chemical companies are actively researching ways to incorporate recycled plastics effectively.

Furthermore, the use of crumb rubber modifier (CRM) from scrap tires is a well-established sustainable practice. Incorporating crumb rubber into asphalt binder not only improves performance (elasticity, rut resistance) but also provides a valuable end-use for millions of waste tires annually. Technologies are continually improving to enhance the compatibility and performance of rubber-modified asphalts. As a manufacturer, we are mindful of these trends and explore sustainable options where feasible, ensuring they meet the necessary performance standards demanded by our clients.

What are the Critical Factors When Choosing a Modified Asphalt Supplier?

Selecting the right supplier for modified asphalt or related products like Coal tar pitch flakes is as critical as choosing the right material itself. For buyers like Mark Thompson, who need reliable, high-quality materials for demanding applications and operate on tight schedules, several factors come into play. Based on our experience working with international clients, here's what procurement professionals should prioritize:

- Product Quality and Consistency: This is paramount. Does the supplier have robust quality control measures from raw material sourcing (base asphalt, polymer) to final product testing? Can they consistently produce modified asphalt that meets specifications (e.g., Superpave PG grades)? Ask for test reports and certifications. Ensure they understand the critical nature of achieving proper polymer dispersion and stability.

- Technical Expertise: Does the supplier understand the nuances of asphalt modification? Can they provide technical support and guidance on selecting the right type of modification (SBS, EVA, reactive polymers like Elvaloy) for your specific application and performance requirements? A knowledgeable supplier can be a valuable partner.

- Production Capacity and Reliability: Can the supplier handle the required volumes and meet delivery deadlines? As a factory with 7 production lines, we understand the importance of reliable supply chains. Delays can halt major projects, so assess the supplier's production capacity and track record for on-time delivery.

- Certifications and Compliance: Look for suppliers adhering to international standards (e.g., ISO certifications). Ensure they comply with relevant environmental and safety regulations. Be wary of certificate fraud – verify credentials where possible.

- Logistics and Packaging: How will the modified asphalt be transported? Is it supplied in bulk, drums, or other forms like blocks or flakes (e.g., Medium temperature asphalt block)? Does the supplier have experience exporting to your region (e.g., USA, Europe)? Clear communication regarding logistics, shipping terms (Incoterms), and documentation is essential.

- Communication and Service: Is the sales team responsive, knowledgeable, and easy to communicate with? Efficient communication can prevent misunderstandings and resolve issues quickly – a common pain point when dealing with international suppliers.

- Pricing: While quality is key, pricing must be competitive. However, be cautious of unusually low prices, which might indicate compromises on quality, modifier content, or service. Seek value, which balances cost with performance and reliability.

Finding a supplier who excels in these areas builds trust and ensures a smooth procurement process, ultimately contributing to the success of your projects.

Real-World Applications: Where are Polymer Modified Asphalts Making a Difference?

The superior properties of polymer modified asphalt make it the material of choice for a wide range of demanding applications where conventional asphalts might underperform. Its ability to resist rutting, cracking, and stripping extends the life and improves the safety of critical infrastructure.

- High-Traffic Highways and Interstates: This is perhaps the most common application. The heavy, repetitive loading from trucks demands excellent resistance to rutting and fatigue cracking. PMA, especially SBS-modified binders, provides the necessary durability to handle high traffic volume and extend pavement service life significantly. Many Departments of Transportation now mandate PMA for high-traffic routes.

- Airfield Pavements: Airport runways and taxiways experience extreme loads from aircraft. Polymer modified asphalt offers the required strength, stability at high temperature (from jet blast and sun), and resistance to fuel spills (depending on the modifier).

- Bridge Decks: Bridge pavements face unique stresses from traffic loads, temperature fluctuations, and de-icing chemicals. The enhanced flexibility, adhesion, and impermeability of PMA help protect the underlying bridge structure.

- Urban Streets and Intersections: Areas with slow-moving or stopping traffic are prone to rutting and shoving. PMA provides the necessary stability.

- Performance-Grade Roofing: In the roofing industry, polymer modified bitumen membranes (often using SBS or APP polymers) offer superior elasticity, weather resistance, and durability compared to standard asphalt shingle or built-up roofing, especially for flat or low-slope roof applications.

- Specialty Industrial Applications: Modified asphalts can also be used in specific industrial settings requiring binders with tailored properties, such as specific viscosity, adhesion, or temperature resistance.

The performance of modified asphalt in these real-world scenarios validates the investment in polymer modification. Using modified asphalt leads to safer, longer-lasting pavements and structures, reducing disruption from maintenance and ultimately providing better value for public and private infrastructure owners. Roads made with PMA consistently demonstrate improved field performance compared to conventional asphalt test sections.

The Future of Asphalt Modification: Trends and Innovations

The field of asphalt modification is continuously evolving, driven by the need for even better performance, increased sustainability, and smarter materials. Researchers and manufacturers like us are constantly exploring new modifiers, additives, and techniques to push the boundaries of asphalt technology.

One key trend is the development of "multiple-stress" binders – modified asphalts engineered to resist a combination of distresses simultaneously (e.g., rutting, fatigue cracking, and thermal cracking) even more effectively than current PMA types. This involves sophisticated formulation using synergistic combinations of different materials and polymer modifiers. Another area is the continued push for sustainability, including improving the performance and ease of use of recycled plastics and crumb rubber in asphalt, and developing bio-based modifiers.

We are also seeing advancements in "smart" asphalt technologies. This includes developing self-healing pavements, where microcapsules containing rejuvenators or healing agents are incorporated into the asphalt mixture, or pavements with energy-harvesting capabilities. While still largely in the research phase, these innovations point towards a future where pavements are not just durable but also interactive and more sustainable. Continued research into polymer science, rheology, and asphalt-polymer interaction using advanced techniques like microscopy and sophisticated rheometer testing will underpin these future developments. The goal remains the same: to create longer-lasting, safer, and more cost-effective solutions for paving and industrial applications.

Key Takeaways on Polymer Modified Asphalt:

- Definition: Modified asphalt is standard asphalt binder enhanced with additives (modifiers), most commonly polymers, to improve performance.

- Transformation: Polymers (like SBS, EVA, Elvaloy) create a network within the asphalt, improving elasticity, strength, and temperature susceptibility.

- Core Benefits: Key advantages include significantly better resistance to rutting, fatigue cracking, and thermal cracking, leading to longer pavement service life.

- Improved Properties: PMA typically offers enhanced adhesion, better stiffness at high temperature, and improved flexibility at low temperature.

- Evaluation: Performance is rigorously evaluated using systems like Superpave and tests such as DSR and BBR to measure rheological properties across relevant temperatures.

- Sustainability: There's a growing focus on incorporating recycled materials like RAP, RAS, crumb rubber, and potentially recycled plastics into modified asphalt mixtures.

- Applications: Widely used in demanding applications like high-traffic highways, airfields, bridge decks, and performance roofing where durability is critical.

- Supplier Choice: Selecting a supplier requires careful consideration of quality control, technical expertise, reliability, certifications, logistics, and communication.

Understanding polymer modified asphalt is essential for anyone involved in specifying or purchasing materials for modern infrastructure and industrial projects. It represents a significant step forward in material science, offering tangible benefits in performance, durability, and long-term value.

Post time: 03-31-2025